Voltage optimisation for businesses: How it works, benefits and costs

Voltage optimisation can be a quick and effective way to reduce your business’s energy bills and carbon emissions by up to 12%, while also extending the lifespan of your electronic equipment.

However, it’s not the right fit for every business. Voltage optimisation works best for commercial properties with voltage-sensitive equipment and where the grid connection consistently delivers over 235 volts.

This guide will help you determine whether your business can benefit from voltage optimisation and calculate your potential savings. Here’s what we cover:

- How voltage optimisation works

- Voltage optimisation costs

- Voltage optimisation savings and payback period

- Pros and cons of voltage optimisation

- How to assess the suitability of voltage optimisation

What is voltage optimisation?

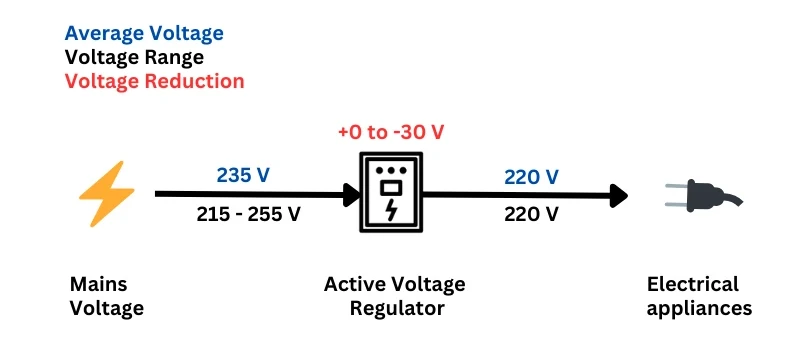

Voltage optimisation is a technology designed to reduce your incoming mains voltage to the optimal level needed by your electrical equipment.

In Britain, the grid typically supplies around 240 volts, whereas most appliances are designed to operate most efficiently at around 220 to 230 volts. This excess voltage leads to wasted energy, unnecessary heat generation, and increased wear on your equipment.

A voltage optimisation system automatically regulates and lowers the voltage supplied to your building to the most efficient level. This helps reduce electricity use, cut your business energy bills, and extend the lifespan of your electrical equipment.

How voltage optimisation works

This section explains how a voltage optimisation unit regulates and reduces the voltage of a business’s electricity supply to the optimal level.

1. Incoming mains voltage

In Britain, the supply voltage of the national grid is 230V with a tolerance of +10% / -6%, meaning voltages can vary from 216V to 253V.

The voltage level at a property depends on the local electricity network infrastructure. Sites located close to an electrical substation often receive a higher average voltage, sometimes as high as to 240V.

Supply voltages are also affected by demand from nearby properties, which means the incoming voltage to a property can fluctuate throughout the day.

The voltage levels mentioned above apply to single-phase supplies, but fluctuating or higher-than-optimal voltages can also occur on 400V three-phase power connections.

2. Voltage optimisation unit

A voltage optimisation (VO) unit is a metal-enclosed cabinet installed between the incoming mains supply and the mains distribution board. Its function is to adjust and regulate the incoming voltage from the grid so that it matches the optimal operating level for your equipment.

When electricity enters a site at a higher voltage than necessary, the VO unit automatically reduces it to the optimal level using transformers or electronic controls. This ensures that all connected systems receive a stable and efficient power supply.

Some VO systems also monitor voltage in real time and respond to fluctuations, keeping the output voltage constant even as the grid supply varies.

3. Output voltage

The output from a voltage optimisation unit connects directly to your building’s main electrical distribution board (also known as the switchboard). All circuits and equipment supplied from that board then receive power at the optimised voltage level.

For larger commercial properties, the output of the VO unit may be connected to specific sub-boards or key circuits to provide more targeted voltage optimisation.

Voltage optimisation costs

A voltage optimisation system requires a significant upfront capital investment, which should pay for itself over time through long-term reductions in energy consumption.

The cost of a system typically depends on the capacity of the specific business electricity connection and the type of system used. Here are indicative prices for single VO unit installations:

| System Type | Typical Cost Range (Installed) |

|---|---|

| Fixed VO Unit | £3,000 – £10,000 |

| Dynamic VO Unit | £7,000 – £25,000 |

| Solid-State VO Unit | £20,000 – £50,000+ |

The prices above include hardware and installation, based on indicative supplier pricing from UK VO manufacturers and commercial installation case studies.

Voltage optimisation maintenance costs

Voltage optimisation systems require minimal maintenance and should continue to operate for between 15 and 25 years before replacement becomes necessary.

Most businesses enter into a support contract with their VO provider, typically costing a few hundred pounds per year, to carry out basic annual checks.

Voltage optimisation savings and payback period

Installing a voltage optimisation system can save British businesses between 7% and 12% on the unit rate charges in their business electricity prices.

We recommend reading the section below on how to assess the suitability of voltage optimisation to understand whether your business is likely to benefit from it.

A well-matched voltage optimisation system can pay for itself in under three years through reduced energy costs and continue to deliver savings for two decades or more.

The calculator below allows you to estimate the annual savings and payback period for installing a voltage optimisation unit for your business.

The savings available from voltage optimisation increase in proportion to:

- Annual power consumption in kWh

- The average unit cost paid to your business energy supplier.

💡At Business Energy Deals, we specialise in helping companies reduce their energy costs. Use our business electricity comparison service today to find out how much you can save.

Pros and cons of voltage optimisation

Here’s a quick overview of the main benefits and considerations of voltage optimisation for commercial sites.

Reduced energy consumption

Common electrical equipment, such as lighting and heating, consumes significantly less energy when supplied with electricity at the optimal voltage level.

Using a voltage optimisation system can reduce the energy consumed at a commercial property, as recorded by a business electricity meter, by up to 12%.

Business electricity bills are calculated based on these meter readings, so a VO unit can lead to substantial reductions in energy costs.

Extended equipment lifespan

When voltage is consistently supplied above the optimal level, it accelerates wear and failure in motors, lighting, transformers, and air conditioning systems.

Voltage optimisation helps equipment last longer, reducing maintenance and replacement costs.

Efficiency and sustainability goals

Installing a voltage optimisation system can support a business’s sustainability goals by reducing the carbon emissions associated with power consumption.

The British electricity grid still relies heavily on gas power stations, which produce CO₂ emissions in proportion to the power they generate. Voltage optimisation reduces the number of kilowatt hours (kWh) consumed, thereby minimising the carbon emissions associated with electricity generation.

The reduction in carbon emissions is particularly beneficial for large businesses participating in the following schemes:

- Energy Savings Opportunity Scheme (ESOS) – Voltage optimisation helps reduce the energy intensity ratio of commercial activities.

- Streamlined Energy & Carbon Reporting (SECR) – Voltage optimisation systems reduce kWh energy consumption and the associated carbon emissions.

Installation complexity and space requirements

Voltage optimisation systems must be installed by a qualified electrical engineer. The installation process usually involves temporarily shutting off power to the property, which may cause a brief disruption to operations.

Additionally, VO units can occupy a substantial amount of space within a plant room or switchgear area.

Limited impact on power factor

Power factor describes how effectively electrical power is converted into useful output. A power factor of 1.0 means that all supplied power is used efficiently, while a lower power factor indicates wasted energy caused by reactive power, which is required to magnetise motors, transformers, and fluorescent lighting.

Most voltage optimisation systems do not actively correct a poor power factor. However, some solid-state voltage optimisation units are available with integrated power factor correction functionality.

Find out more in our guide to reactive power charges.

Types of voltage optimisation units for businesses

Voltage optimisation systems are available in several configurations, each designed to suit different site conditions and levels of voltage variation. The main types (fixed, dynamic, and solid-state) all perform the same basic function of reducing incoming voltage, but they differ in how precisely they control it.

The table below summarises the key characteristics of each type, including how they work, their advantages and limitations, and the kinds of commercial sites they are best suited to.

| Type | How it works | Advantages | Disadvantages | Best for |

|---|---|---|---|---|

| Fixed Voltage Optimisation | Reduces incoming voltage by a fixed percentage (typically 4–6%), lowering the average supply to around 220V. | Simple, low-cost, reliable, and easy to install. | Does not adapt to voltage fluctuations, so may under-supply during low-voltage periods. | Sites with consistently high mains voltage and equipment not highly sensitive to small voltage changes. |

| Dynamic Voltage Optimisation | Monitors and adjusts output voltage in real time to maintain a set target level (e.g. 225V). | Provides stable, efficient voltage even under varying grid conditions and delivers consistent savings. | Higher upfront cost; more complex to install and commission. | Sites with variable supply voltages or sensitive electronic equipment. |

| Solid-State Voltage Optimisation | Uses advanced electronic controls for precision regulation and can also provide reactive power optimisation. | Offers the highest accuracy and efficiency. | Most expensive option; requires more space and may need a temperature-controlled environment. | Large or complex sites with three-phase supplies or critical voltage-sensitive loads. |

How to assess the suitability of voltage optimisation

Voltage optimisation is typically only beneficial for your business if your site consistently receives mains voltage above 235V and uses energy-intensive equipment that is sensitive to voltage fluctuations.

This section explains how to determine whether these conditions apply to your business.

Assess electrical equipment for voltage optimisation

Whether voltage optimisation is suitable for your business depends on the types of electrical equipment in use.

Some equipment is highly sensitive to voltage and can achieve noticeable energy savings, while other equipment already regulates voltage internally, meaning optimisation makes little or no difference.

The table below shows the potential energy savings from voltage optimisation for different types of equipment:

| Device Type | Examples | Load Type | Energy Savings Potential |

|---|---|---|---|

| Incandescent Lighting | Halogen lamps, traditional filament bulbs | Resistive | High |

| Electric Heaters | Space heaters, panel heaters | Resistive | High |

| Induction Motors | HVAC fans, pumps, lifts, compressors | Inductive | Medium to High |

| Refrigeration Equipment | Commercial fridges, freezers, cold rooms | Inductive | Medium |

| Fluorescent Lighting | T8/T12 tubes with magnetic ballasts | Inductive | Medium |

| LED Lighting | Modern LED panels or bulbs | Electronic | Low |

| Computers & Servers | Office PCs, network equipment, data centres | Electronic | Low |

| Audio-Visual Equipment | Televisions, projectors, sound systems | Electronic | Low |

For more information on assessing the relative energy use of electrical equipment, visit our guide to business energy consumption.

Overall power demand

Investing in voltage optimisation equipment is typically not worthwhile for small business energy customers with low power demand, as the potential savings are likely to be minimal.

Instead, we recommend considering voltage optimisation solutions for properties with a Maximum Import Capacity exceeding 100 kVA and a half-hourly energy meter.

Power quality assessment

Before investing in voltage optimisation equipment, it is essential to assess the voltage levels supplied to your property.

Some properties may already receive a stable 220V supply, making voltage optimisation unnecessary.

The voltage supplied to an individual property depends on the local infrastructure of your distribution network operator and the power demand from other nearby properties.

A professional power quality assessment involves connecting a voltage data logger to your mains supply to continuously measure voltage variability over a representative period of one or two weeks.

If the recorded voltage is consistently:

- Above 235V: Voltage optimisation is likely to deliver significant savings.

- Within 220–235V: Voltage optimisation may offer only limited benefits.

Installing voltage optimisation in a commercial property

This section summarises how a voltage optimisation provider installs a VO unit at a commercial property.

Site survey

A voltage optimisation provider will typically carry out an on-site survey to recommend the appropriate VO type and capacity, and to estimate the potential energy savings and return on investment for your specific property.

A site survey will typically:

- Review the distribution board layout

- Identify main loads and circuits

- Consider any sensitive equipment that may need bypassing

- Determine whether a fixed or dynamic system is most suitable

- Establish the system’s capacity requirements

The provider will issue a technical proposal and cost quotation following completion of the site survey.

Installation and commissioning

A voltage optimisation provider will arrange for a certified electrical engineer to install the equipment.

VO units are typically fitted between the incoming mains supply and the distribution board.

To minimise disruption from the temporary power outage required, installation is often scheduled for evenings or weekends.

Integration with EMS

A voltage optimisation system can be integrated with an Energy Management System (EMS) to provide live voltage readings, log voltage fluctuations, and record fault events.

Post installation verification

After installation, the voltage optimisation system should be checked to confirm that it is operating as designed. The installer will typically record input and output voltages, verify the expected voltage reduction, and ensure that all equipment is functioning correctly.

Some providers issue a verification report showing measured voltages, energy reduction, and power quality performance.

Energy use can be compared with pre-installation data from your electricity meter to confirm that your VO system is delivering an improvement in business energy efficiency.

Expected installation timescale

The complete voltage optimisation installation process typically takes between four and eight weeks.

Here’s what to expect at each stage:

- Initial assessment and site survey: 1–2 weeks

- System design and planning: 1–2 weeks

- Equipment procurement and preparation: 1–3 weeks

- Installation and commissioning: 1 day on site